Description

Pulses Dal Mill Machine 6FW-P24B2

Pulses Dal Mill Machine 6FW-P24B2 adopt our unique patented peeling technology. Easy to operate, the skin, kernel and black navel are separated cleanly, there are few broken beans, and the peeling effect is excellent. The workshop has no special requirements, the equipment has a compact structure, a small floor area, low energy consumption and high work efficiency. Please know more at below:

Pulses Dal Mill Machine Main Parameters

| Model | 6FW-P24B2 |

| Raw material | chick peas, yellow peas, soya beans, garden peas, green peas, etc. |

| Production capacity | 1000KG/H |

| Motor power | 12.3KW |

| Net weight | 1000kg |

| Dimension | 2400*1000*3000mm |

| Peeling performance rate | 98% |

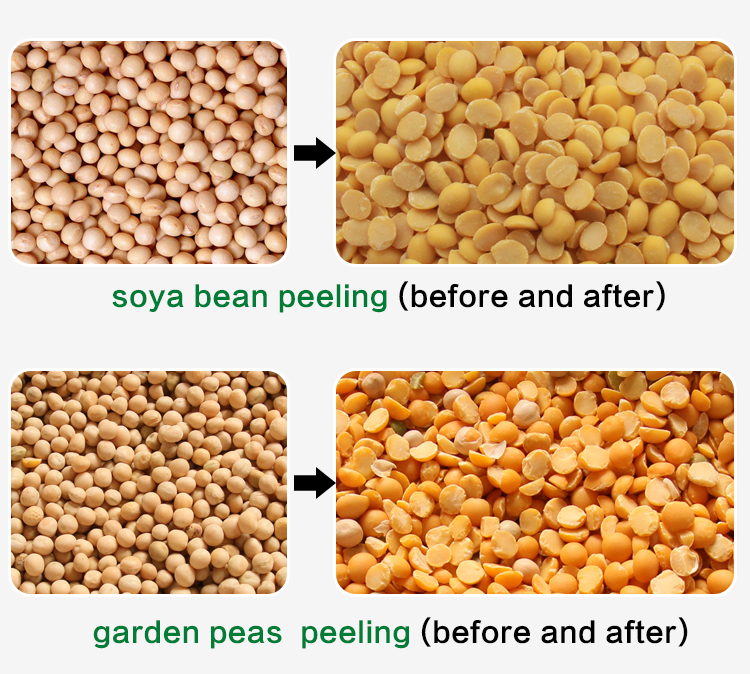

Finished product of Pulses Dal Mill Machine

Great performance

- High output percentage rate with very low rate of bean flour or grits.

- Peel one time, no need to repeat. Split beans into half size in good color and nice fresh smell.

Multifunction

- Multiple functions to peel yellow peas, soya bean, garden peas, etc.

- clean the skin, peeled beans and black door beans separately, with very few broken beans, perfect peeling effect. It is an ideal equipment for pulses processing plants.

Pulses Dal Mill Machine Main Detail

Main Structure

- This machine is composed of peeling system, round sieve system, wind web dust control system, gradeless crushing handle, hopper, feed insert plate and machine frame, etc.

- Complete Processing team

Raw material hopper—-Elevator—-Peeling system—-Bran brusher

Basis introduction

- Complete dal peeling processing team.

- Peel beans in dry way, no need any water in whole process.

- Surface treatment adopts powder coating. Prevent rust and scratches. Long service life and durability.

- Now our equipment has been updated and upgraded, the service life is 5 years longer than traditional machines, and the rate of finished products yield is 5% higher than traditional machines. It is the most advanced beans peeling machine so far in China.

Working Video For beans Peeling Machine

- This video is processing mungbeans.

- Super low motor power, saves electricity and saves production cost.

- No special requirements for the plant, installed on the concrete floor, keeping the ground level.

Machines For Other Processing

Corn Production Line

Whole line includes cleaning, peeling, flour milling, etc. All process goes automatically. The finished product can be grits or flour.

Peeled Whole Size

Process to peel off beans skins, peel one time beans skin for better quality flour. Peeled whole side. Can peeling multiple grains.

Flour Mill Machine

Process to mill the peeled corn into very fine flours for human consumption or crush whole corn into corn meal for food or animal feed.

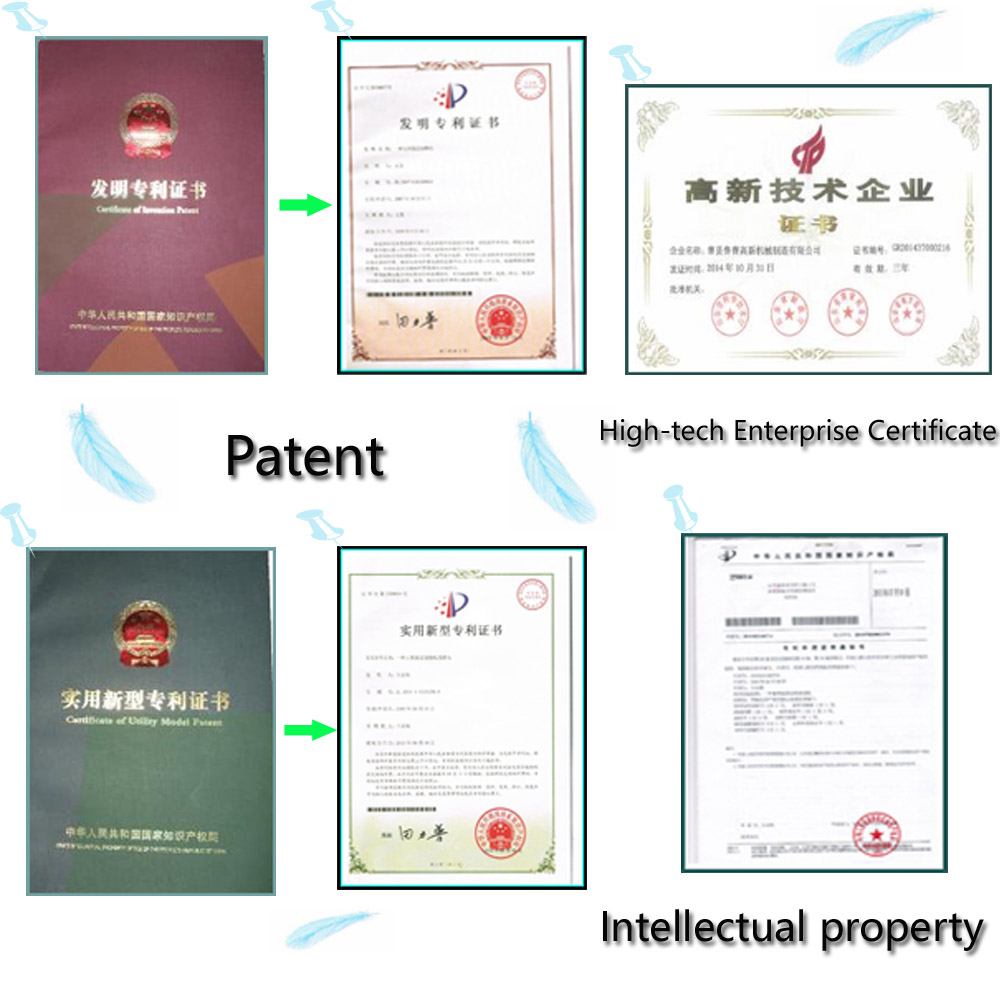

Shining's Certificate Patent

We already have 25 national invention patents, and 15 more are pending. We can design and manufacture a complete set of corn flour mills with a daily output of more than 500 tons. This is impossible for other factories.

- Industry-leading R&D capabilities;

- Excellent unique design and performance;

- Comply with ISO 9001 and CE standards;

- Constantly focus on research and innovation.

Contact Us

Pulses Dal Mill Machine 6FW-P24B2 is our patented research and development technology, low maintenance cost. The main body shell is powder-coated and thickened to make the equipment cleaner and more durable.

We can design as your demand (production capacity, and quality…). If you are interesting in our products, pls tell me your contact information in our e-mail.